Air Release Valve Application Range

-

Water transmission

-

Water distribution

-

Pump suction line

-

Peaks and bottom points

-

Next to by-pass valve

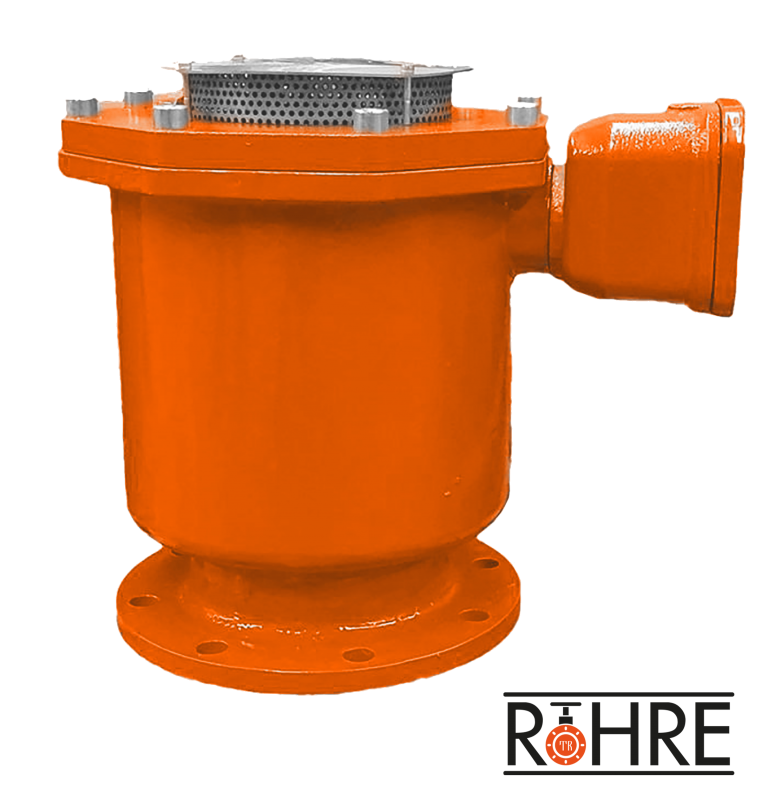

Air Release Valve Product Features

-

Float parts made of polyethylene, increase the corrosion resistance, hence increases service life.

-

The polyethylene floats gives advantage for easier replacement.

-

Ductile iron body increases the resistance against impacts.

-

It is necessary to use air release valves on the peak points of the pipelines, in order to maintain the full flow of the water.

-

If the air vacuum via air release valve is less than the discharged water amount, the pipeline will face the risk of torsion.

-

Fully coated body and bonnet, meets the hygienic requirements of the potable water networks. (WRAS coating optional)

-

Double orifice air release valve is installed on the pipe by a flange, release the air received from its outlet through the orifices located above the float parts.

-

When the air release function is completed, the floats travel upper part with the water force and close the orifice outlet, thus preventing the leakage of water.

-

Flange connections according to EN1092-2/ISO 7005-2. Working pressure range from 0.2 to 16 bar.

-

Hydrostatic test pressure for seat: PN x 1.1 , for shell: PN x 1.5 according to EN 12266-1.